Artwork Specifications

The artwork is an important part of your product. That is why you must also take the utmost care here. Please read the specifications and instructions carefully.

Our specifications and templates are clear to someone experienced who knows what he or she is doing. We print everything as it is delivered to us, therefore, we are not liable for any errors that occur if you do not apply them correctly. We will not send you hard or soft print proofs before we print the files. However, nothing can go wrong if you follow our instructions and specifications. Make sure it is designed by someone who knows how to deliver a print-ready file or ask us to design your artwork.

File Format

- Please send us 300 dpi flattened .PDF files in CMYK (or Pantone) based on our templates only. We do NOT accept INDD/.PSD/.AI/.EPS or any other files.

- Save as PDF/X-1a:2001/1.3, exported without scaling or compression. Other PDF versions may cause transparency issues!

- Save your artwork in the ICC color profile – FOGRA39.

Catalog Number

- Make sure to include the Catalog Number of your project in each file in the following way:

Your Cat. No. – Artwork Type

For example:

DEEP001 – Outer Sleeve (or Label/Inner Sleeve etc…)

- Please use the same Catalog number as you used for the Info Sheet. You can also find it on your quote or invoice.

Templates

- Artwork templates can be found here: deepgrooves.eu/templates.

Always use our templates. Do NOT use those of other suppliers. We are not liable for any errors that occur if you do not use them. - Do NOT save the template or any visible cutting, folding and punching lines or color bars in the design you send us. Send us the finished and clean design only.

- Fill the cut-out holes of the labels and sleeves with artwork. Please do NOT spare!

- Please make sure to delete the template layer before exporting your file, to avoid unnecessarily large files.

- Bleed for Labels, Sleeves, Inserts is 5mm extra on all sides. Stickers 2mm, Stamps 0mm.

Fonts

- Convert fonts to paths or embed them in the file. Sometimes we cannot link the fonts used in the design of your file when opening or printing it.

- Fonts must be a minimum of 4 pt for positive printing and a minimum of 6 pt for negative printing. Also pay attention to the minimum line thicknesses for very fine fonts.

Line thicknesses

- Line thicknesses may not be less than 0.15 mm in positive printing and 0.25 mm in negative printing.

- Line thickness for hot foil and embossed printing should be at least 0.35 mm.

- Fonts should be at least 5pt in positive printing and at least 7pt in negative printing. Please pay attention to our minimum thicknesses for exceptionally fine fonts.

Colors

- ICC Color Profile: FOGRA 39

- Black characters and lines with a CMYK background should be overprint.

- Knock (cut) out Pantone/HKS colors in the design.

- The sum of all colors may not exceed 280% of the print coverage.

- Cold Rich black = 40% Cyan and 100% Black.

- Warm Rich Black = 30% Cyan 20% Magenta 20% Yellow 100% Black.

- Warm Rich Black = 40% Cyan 50% Magenta 50% Yellow 100% Black.

- Please note that we have a dot gain of about 15% from the file to the print. Be sure contrast for dark colors is at least 15%, for labels or rough paper even 20%. So that the individual elements can still be distinguished from one another even after printing.

- Embed all Pantone color information in the design.

Uploading Your Files

- After payment of your invoice, you will receive all information about uploading your files.

- Please do NOT send us a WeTransfer or other download link via email. Upload your files via your Deepgrooves Dashboard only. To keep things organized we will ignore all other file transfers.

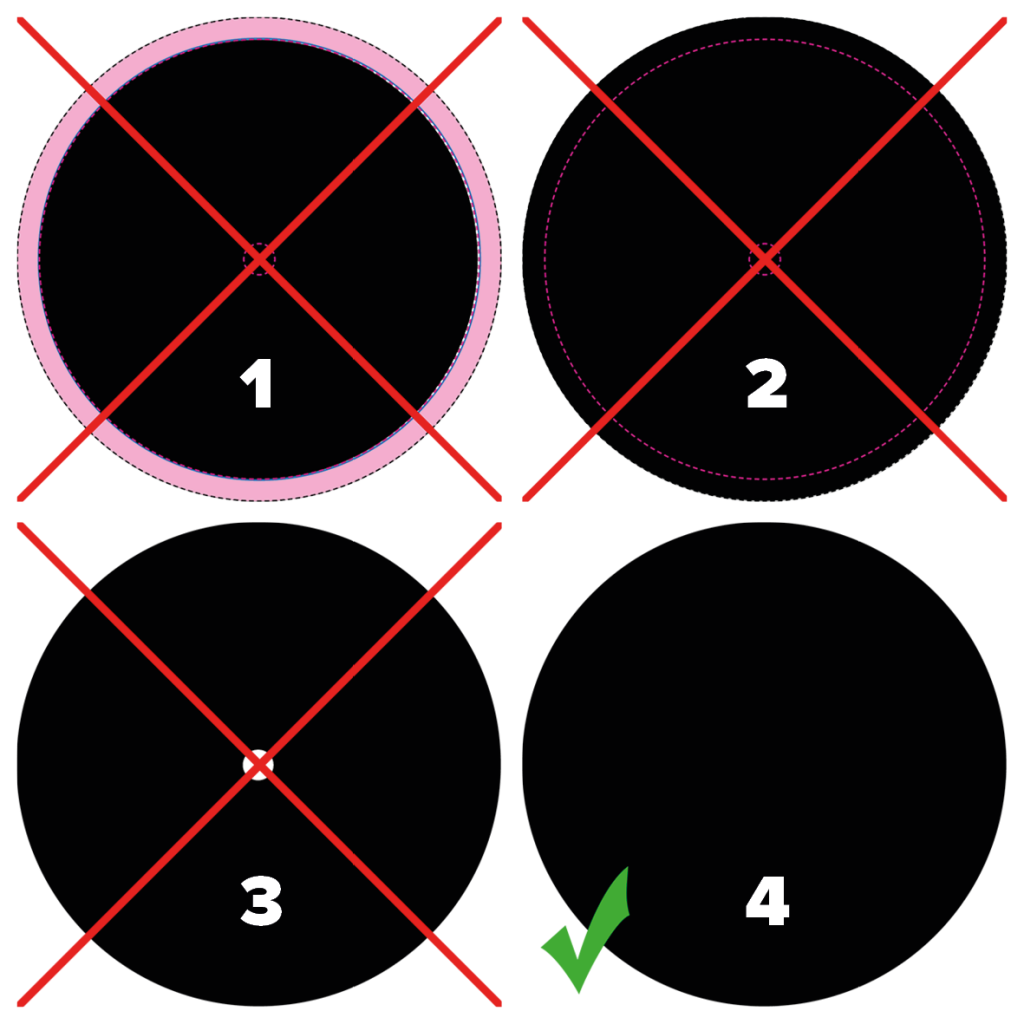

Some of the things we often see going wrong with the labels:

2. Leaving the template guides visible in the design. Your label will be cut out here. If you leave them in the file, they will be printed and may be visible.

3. The hole in the middle is not filled with artwork. This can cause white edges on the final print.

4. This is the right way! 100mm with 5mm bleed on each side, final file is 110mm with no visible template or design guides.

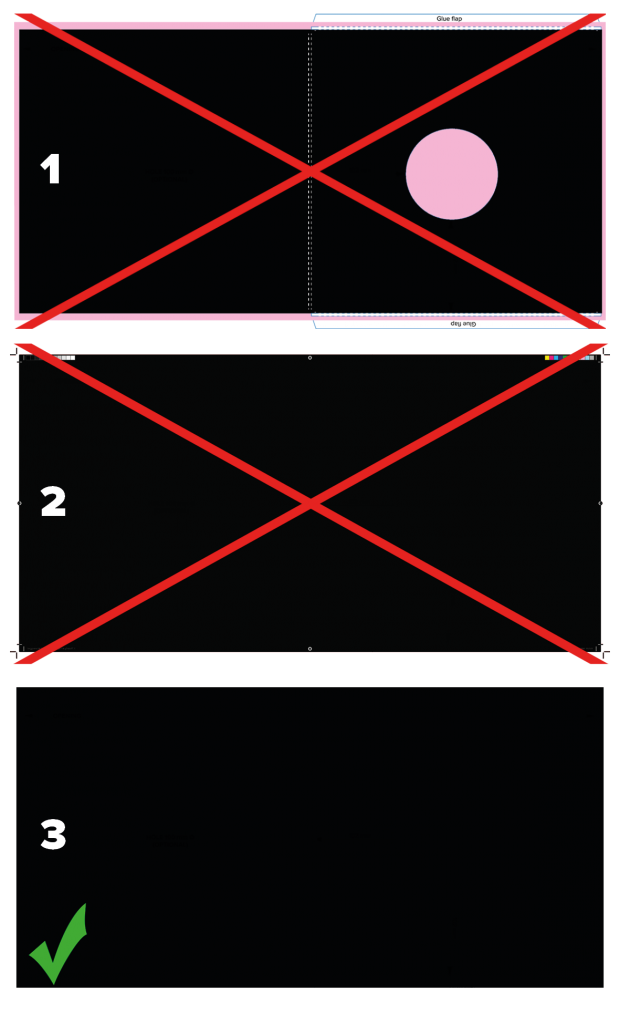

Some of the things we often see going wrong with the sleeves:

2. We don’t need any printer marks in the file you upload to us.

3. This is the right way! The exact size of the sleeve with 5mm bleed on each side. No visible template or design guides.